In House Reactors &

Purification units for your Experiments; performed and analyzed by PRT.

Reactors

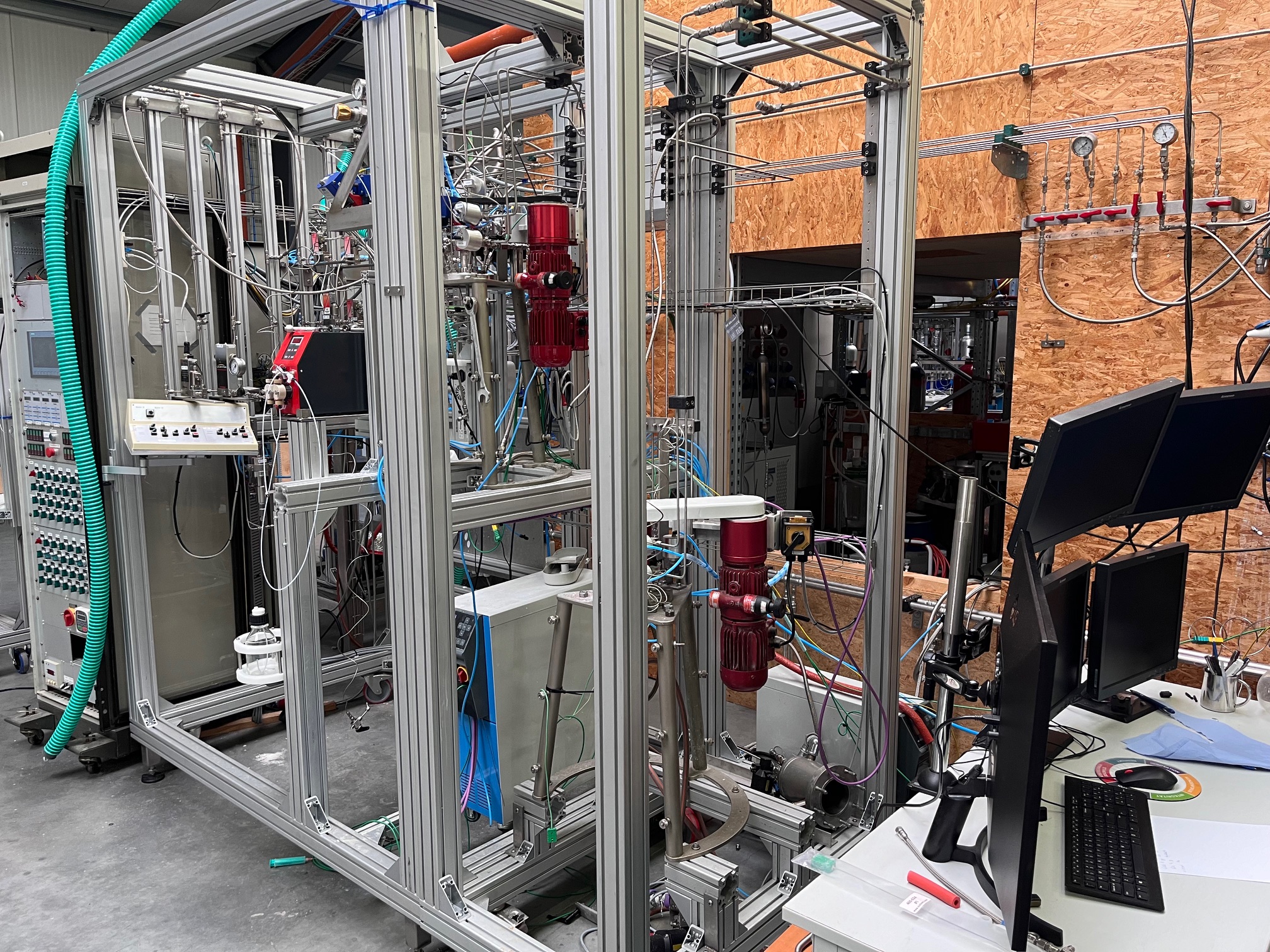

Multi purpose reactors

PRT GmbH provides different stainless steel jacketed multipurpose batch reactors for olefin polymerization. Our reactor systems are mounted in mobile stainless steel frames. The combination of the reactor, feed supply, injection and temperature control makes such a system a mobile plug-and-play tool. The reactor system is made for catalytic olefin (co-) polymerizations with precise hydrogen- and co-monomer concentration control. Slurry, gas phase, and high-temperature solution polymerizations can be carried out. Of course, these reactor systems can be used for free-radical polymerizations in emulsion, bulk, and suspension too. For catalytic olefin polymerizations, the system comes optionally with controlled purification units developed by PRT.

Our integrated aproach comprises all the essential elements of catalytic and free-radical polymerization technologies.

We offer batch, as well as continous mode operation experiments. The produced polymer qualities can be analyzed.

All of our liquids are purified before beeing used in our experiments!

| Volume range | 0.5 – 300 L |

| Pressure range | UHV -250 bara |

| Temperature range | 10-220 °C |

The reactor itself can be optionally equiped with:

- Bottom valve for sampling

(when internal heater is not present) - Interchangable stirrers

- Elevator system for easy handling

- Stirrer speed control

- Calorimetric measurement

- Multistage safety system